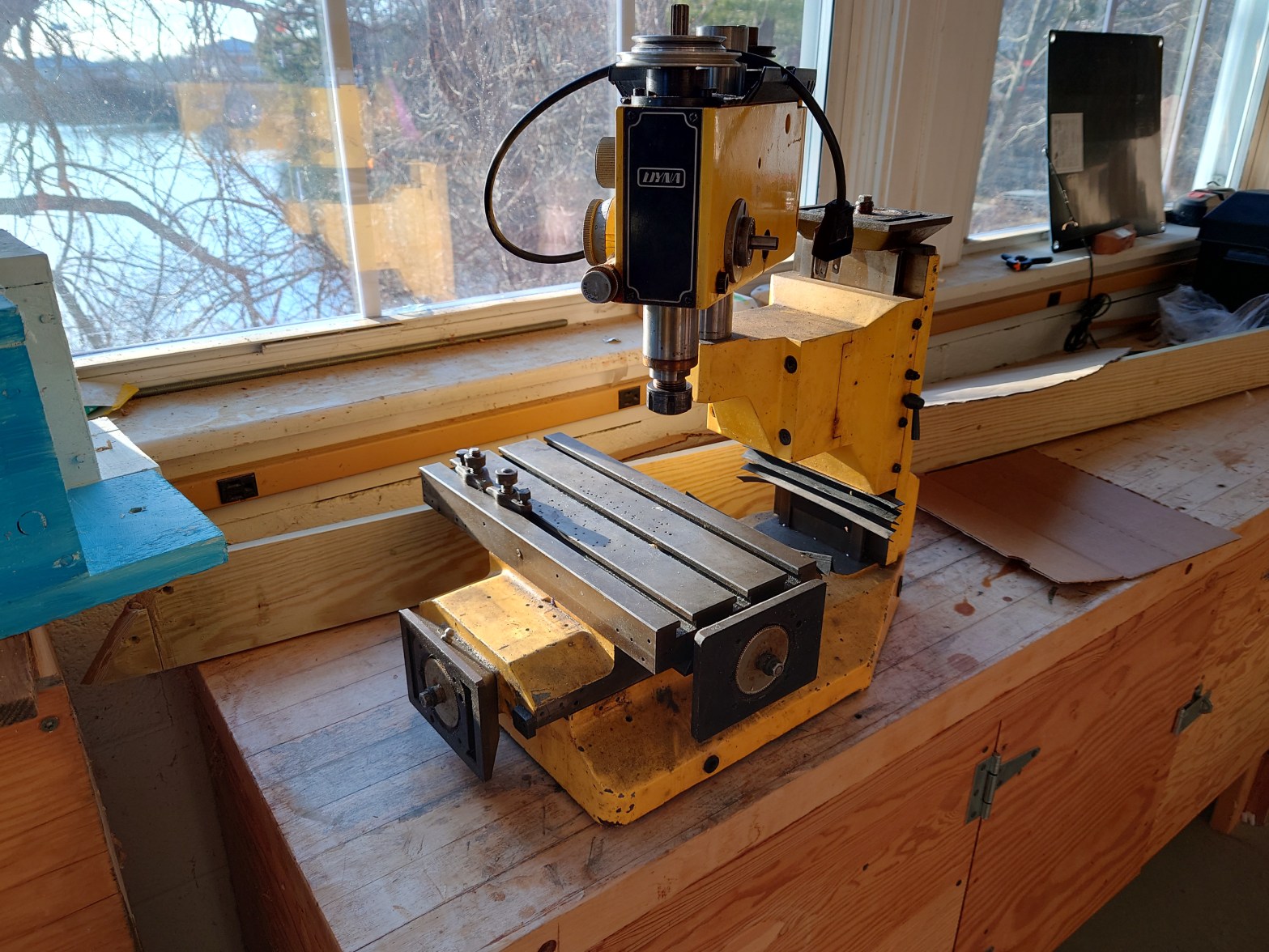

The DynaMyte DM2000 is a miniature desktop mill from the 80s that was set up for CNC control. There were other various models, including the highly sought after DM2400 with a larger workspace. The hallmark of all of their machines is their high rigidity and sheer heft, which is in direct opposition to the recent proliferation of ‘desktop mini-mills’ with linear rail bearings on aluminum frames.

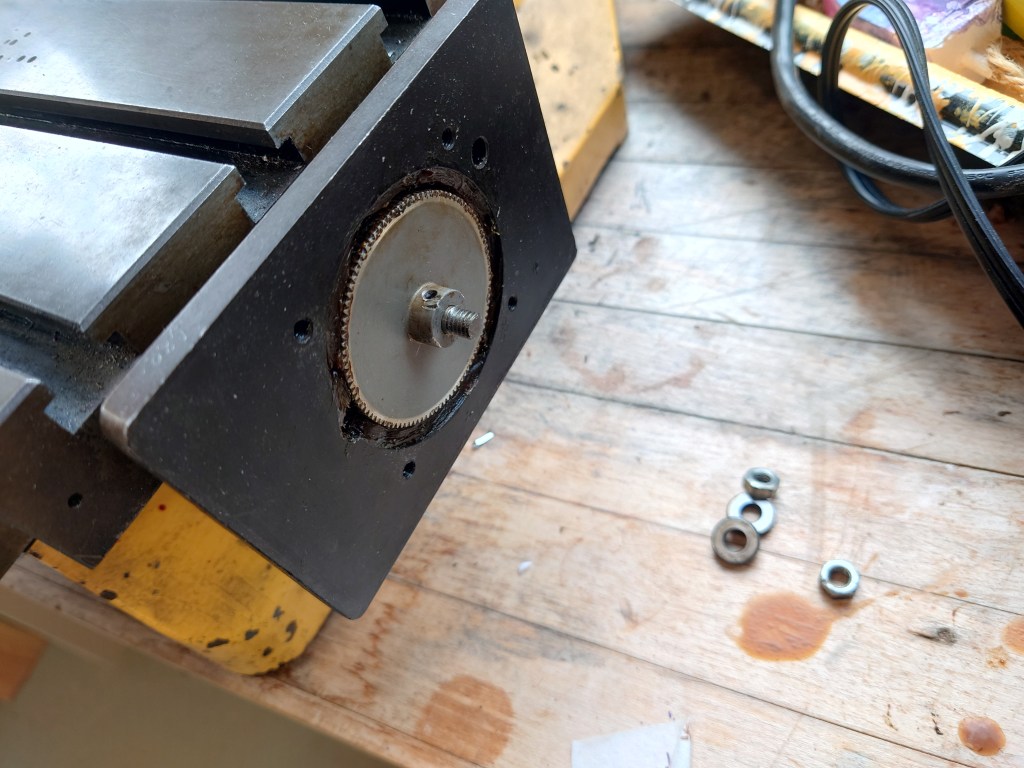

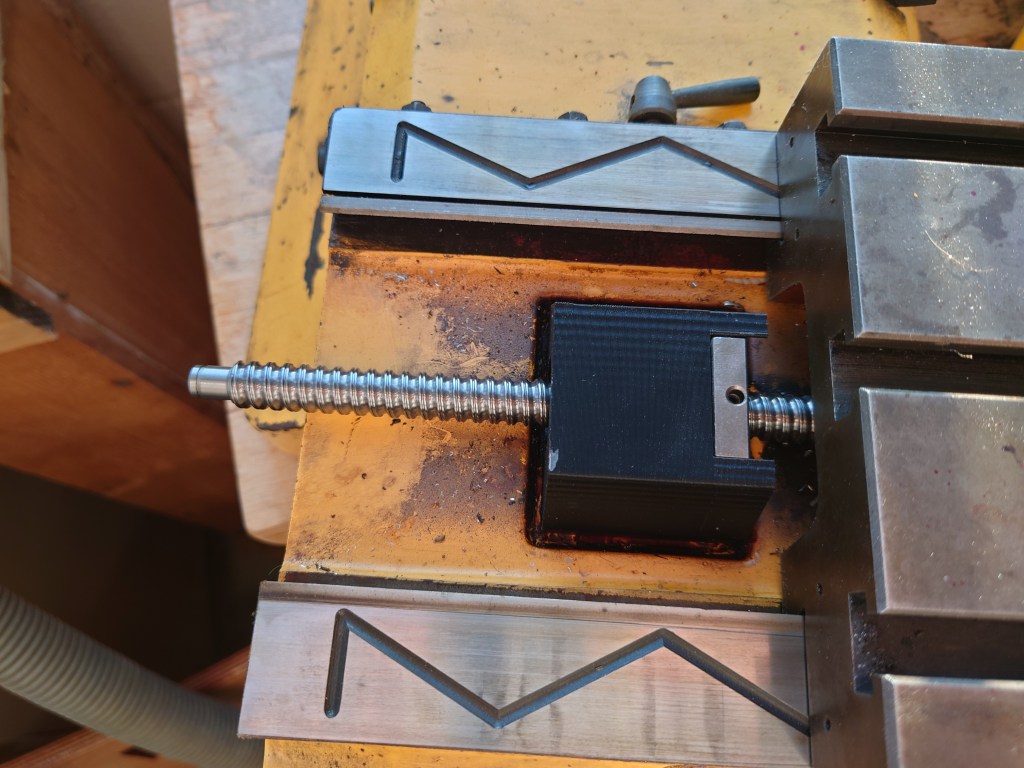

I picked up a defunct machine recently and have started the process of replacing the worn parts, cleaning it, installing new servos, ballscrews, and controllers so that I can return the mill to operation.

Metric? Standard?

The teardown was pretty straightforward, however I’ve had a hard time tracing out some of the dimensions from some of the parts. Before I purchase material for new mounts, I want to ensure that the dimensions I’ve reverse-engineered are correct. I’ve employed a few 3d-printed mockups of the future parts to prove out my concepts.

For example, I went through a few iterations and choices for interfacing parts for the motor/bearing mount. Additionally, the ball-nut mount that will be attached behind the slides. I want the pieces to be as rigid as possible, so they are not the failure point for dimensional drift.

More to come on this project as I make more progress! 🙂

Next steps will be:

- Finish teardown and clean the frame.

- Fabricating the motor mounts.

- Purchasing the servos.

- Drafting the electronics enclosure

- Choosing control solution (like GRBL)

- Forming the enclosure (or contracting out)

- Fabricating the ball-nut mounts.

- Assembly

One thought on “DynaMyte DM2000 CNC Mill”